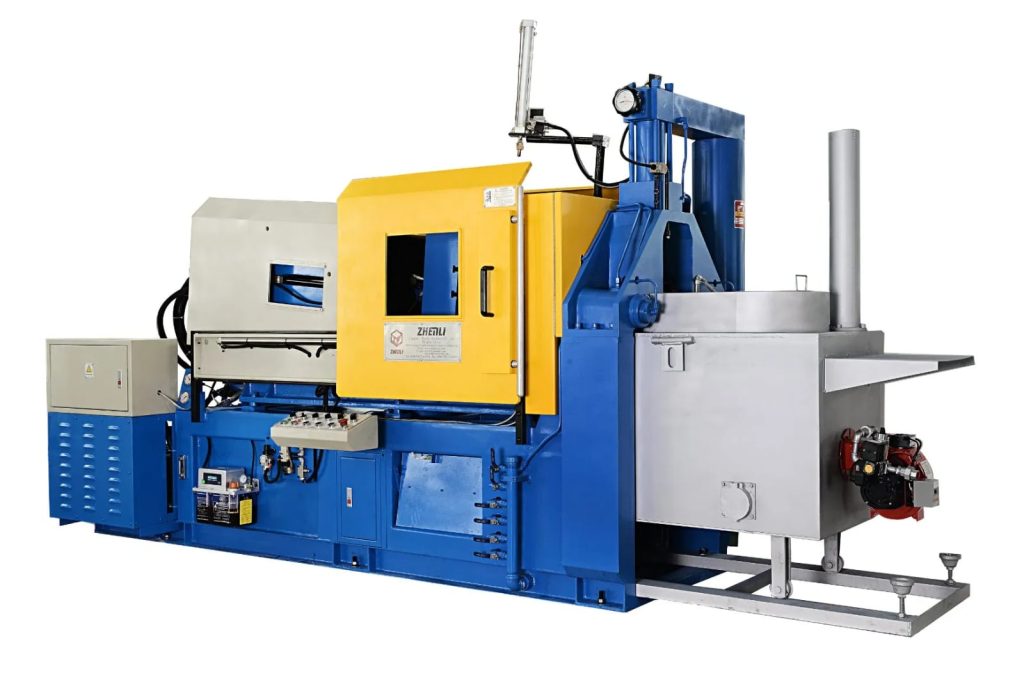

HOT CHAMBER DIE CASTING MACHINE

Hot Chamber Die Casting Machines are integral to industries that require the efficient production of high-precision metal parts. By keeping the metal in a molten state within the chamber, these machines offer faster cycle times and greater efficiency compared to other casting methods. The process involves injecting molten metal into a mold under high pressure, allowing for intricate designs and complex geometries. These machines are primarily used for metals like zinc, aluminum, and magnesium alloys, and they are known for their ability to produce consistent, high-quality parts with minimal defects. Due to their speed, precision, and low operational costs, hot chamber die casting machines are widely used in industries such as automotive, electronics, and medical device manufacturing. Their ability to handle complex shapes and high-volume production makes them an essential tool in modern manufacturing.