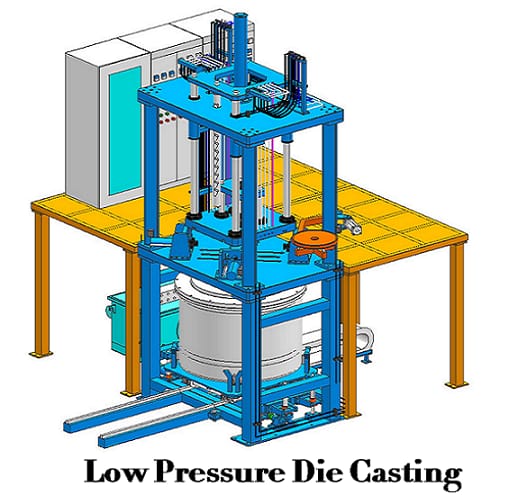

LOW PRESSURE DIE CASTING MACHINE

Low Pressure Die Casting (LPDC) Machines are widely used for manufacturing high-quality, complex metal components with excellent strength and dimensional accuracy. Unlike traditional high-pressure casting methods, LPDC operates by injecting molten metal into the mold under controlled low pressure, typically between 0.1 to 1.0 bar. This slow and steady filling process reduces turbulence, minimizing porosity and improving the overall mechanical properties of the casting. LPDC is especially suitable for aluminum and magnesium alloys, making it a preferred choice in the automotive, aerospace, and industrial sectors for producing wheels, engine blocks, and structural components. The process offers high material utilization, minimal defects, and the ability to produce thin-walled, lightweight parts with superior surface finish. Its cost-effectiveness and ability to create intricate designs make LPDC an ideal solution for precision-driven industries.